Wednesday, 31 October 2012

Geoffrey Entwistle Planemaker RIP

I'm sad to report the death of plane maker Geoffrey Entwistle in a Hospice over the weekend, my condolences to his family. I came to Geoffrey's work late in his career and unfortunately we never actually met, although in our e mail exchanges he was very courteous and unassuming for one with such talent.

Geoffrey kept a lower profile than some of our other plane makers but was no less able than the very best. I know from conversation I have had with his contemporaries his work was universally admired.

I would appreciate it if you all could circulate this sad news around the wood working community.

I will leave you with some pictures of his work which I think speak for themselves.

Sunday, 28 October 2012

Dovetail Guide Review 'F&C Magazine'

This months Furniture and Cabinetmaking magazine carries a review of magnetic guides which includes a page on my Dovetail Jig written by John Bullar http://www.bullar.co.uk/index.htm

John used my guide with a narrow bladed English style saw, completing the cut by dropping the saw guide down so that the magnet was against the side instead of the top. This seemed to have worked very well and I'll add this technique to my repertoire.

The Veritas Dovetail guide was also reviewed and whilst considered accurate was also thought to be rather slow and rigid in the way it worked. It is also more than twice the price!

The review above speaks for itself, if you would like a PDF of the whole article please e mail the Editor Derek Jones at derekj@thegmcgroup.com

Friday, 26 October 2012

Boxwood Mitre Plane.

Berin sent me some pictures of this mitre plane he made from spalted boxwood and a fine job he has done too. Shown before being soaked in oil against a rather dramatic spalted beech cabinet.

He was inspired by the plane by Tim Smiths mitre plane http://davidbarronfurniture.blogspot.co.uk/2012/06/tim-smith-mitre-plane.html

and of course Bill Carter http://www.billcarterwoodworkingplanemaker.co.uk/

End grain shavings on some yew seems to work well.

And here he is the man himself, in a well organised and cosy looking workshop. He has a very active and interesting blog which is well worth a look http://www.berinsblog.blogspot.co.uk/

Thursday, 25 October 2012

Dream Workshop!

No it's not my workshop! It belongs to Kent Adkins and you can see a video of it here http://www.popularwoodworking.com/woodworking-blogs/chris-schwarz-blog/european-dreaming-a-visit-to-kent-adkinss-shop

It's a lovely building with a huge amount of space and just look at that machinery!

I've had a few conversations with Kent recently and he sent me these pictures of a current project in butternut. This is not a wood I'm familiar with in the UK but apparently it's a cousin of walnut.

Here is a magnificent figured board of butternut with some nice figuring for the top. It measures an impressive 82'' x 22'', well if you have that sort of machinery you might as well make the most of it!

Tuesday, 23 October 2012

Shaping on the Band Saw

Shaping of my smoothers is a lot easier and quicker than you may imagine. The glued up blank is marked up on the side and base, I use perspex templates.

The first cuts are to the heal and toe. Notice that the plane is bottom up so that the ragged edge is in the waste. The blade is a 1/2" 4 TPI which just about makes it round the curve!

Here is the result.

The plane is then turned on it's side and the two profile cuts are made.

Next comes the curved shaping of the rear end, this is potentially very dangerous and I'm just showing you how I do this shaping, I'm not recommending that you try it. Both James Krenov and Sam Maloof were advocates of this technique.

I always make sure I follow a number of rules 1. Make sure the work is in contact with the table at all times

2. Keep the hands away from the blade and above the point of cut.

3. Only remove a small amount of material at a time.

4. Cut slowly and never force the cut.

5. If the blade starts to grab, back the cut out and start again.

It takes me about 4 minutes to do all the shaping cuts and turn the plane blank into a comfortable and usable shape, albeit a bit rough!

Here is the shaped plane with it's offcuts, this dense wood burns very well, nothing goes to waste!

Sunday, 21 October 2012

Resin Glue.

I've been making a batch of 10 smoothers and jack planes. The picture above shows the squeeze out from polyurethane after gluing on the lignum vitae soles, no other glue would be suitable for this very oily wood.

Up to now I've used Titebond yellow glue for gluing the plane sides on, this works well but can creep slightly over time which makes the glue line detectable with your finger tips.

When I trained at the Barnsley Workshops their glue of choice was a powdered resin glue such as Cascamite and I know Alan Peters used this a lot on his furniture. It dries rock solid with no creep at all, but is is more fiddly to use requiring accurate mixing, 30 gr of powder to 15 gr of water. Digital scales come in very handy for small amounts, they just require sneaking in and out of the kitchen when the wife isn't looking!

After about 30 seconds of mixing here is the result ready for use. It has a much longer open time than yellow glue which is nice but it takes longer to fully harden especially if it's cold. Also whatever is left has to be discarded.

This is dried glue line on the inside of a smoother, thankfully I sealed and waxed the interior before glue up, so the beads just popped off with a sharp chisel.

I had noticed that James Krenov used resin glue when he made his planes, here are some of the glue beads left on the inside of one of his planes.

Here is a shot of the whole plane, he made this when his eye sight was fading, not pretty but very comfortable to hold. Handling a few of his planes helped me a lot with my plane designs, although I don't think I would sell very many if I left them straight from the band saw!

Friday, 19 October 2012

Antique Woodworking Magazines

I visited Dansell Gallery recently to take down some more stock and Danielle showed my a couple of boxes of old woodworking magazines. The earliest of them dated back to 1914, almost 100 years ago and I couldn't leave without buying two. They cost me £5 each which was good value for something as rare and old as this, although when I looked at the cover price 3d I realised that was about 1.5 pence (1 cent) in today's money! She has plenty left if anyone is interested http://www.danselgallery.co.uk/

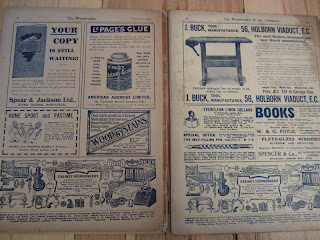

Here is a shot of the back covers, the adverts were fascinating and more interesting than the articles inside!

J Buck was advertising a work bench for under £2, albeit a flimsy looking thing.

A nice article on a tool chest with measurements.

This is an interesting advert for a sharpening jig which could easily be made in the workshop.

The articles and text look very similar to the layout of the early copies of Fine Woodworking.

Here is a lovely piece from the Gallery with sculpted end panels.

Some tables in the upstairs gallery.

As well as furniture they stock a selection of my planes and other tools which have been selling very well this year. The jointer in the background is an extra long 22" plane, it's a beast!

Wednesday, 17 October 2012

First time dovetails!

A customer kindly sent some pictures of the first dovetails he had cut, I wish mine had looked like that!

Keith said he was amazed at how easy the magnetic guide was to use. He also stated that the usefulness of my dovetail alignment board could not be underestimated, it certainly beats the old fashioned method of balancing the tail board on a plane.

Anyway, well done Keith they look very nice cabinets.

Tuesday, 16 October 2012

Dovetail Marking Knives

I've just finished a small batch of 21 (why 21?!) dovetail marking knives. Here are the parts laid out for finishing and final assembly.

I purposely left some sapwood in the some of the last lot of handles and I've used one of them in the batch. The sapwood on African Blackwood is just as hard as the heart wood and gives a nice contrast especially when finished to a high standard.

The Pink Ivory is a shocking pink colour and stunning. It will hold this colour as long as it is kept out of direct sunlight, otherwise it goes a brown colour in time.

Snakewood is the most popular despite the extra cost. Unfortunately it is getting very difficult to get hold of and I'm down to my last 20 or so blanks.

Brazilian Tulipwood completed the very colourful batch. All these woods have an SG of 1 or more and wood sink if put in water, perish the thought!!

Sunday, 14 October 2012

Nakashima Style Wall Cabinet

The new edition of Furniture and Cabinet Making has an article by me on the making of a Nakashima style wall cabinet using some wonderful English Walnut. I'm getting good publicity this month!

The article outlines the making along with a detailed plan and dimensions. Anyone wishing a free copy (of the article) can contact the editor Derek Jones via e mail derekj@thegmcgroup.com and he will gladly forward a PDF.

There were some pretty meaty through dovetails on the corners but everything went together well.

Coming next month is an article on saw guides including a review of my magnetic dovetail guide. The picture below shows the guide being used in an unconventional manor and with a narrow bladed English saw instead of a wider bladed Japanese saw. I'll be intrigued to see what they think, but I'm also slightly worried!!

Subscribe to:

Comments (Atom)

.JPG)

.JPG)

.JPG)